Project Timeline

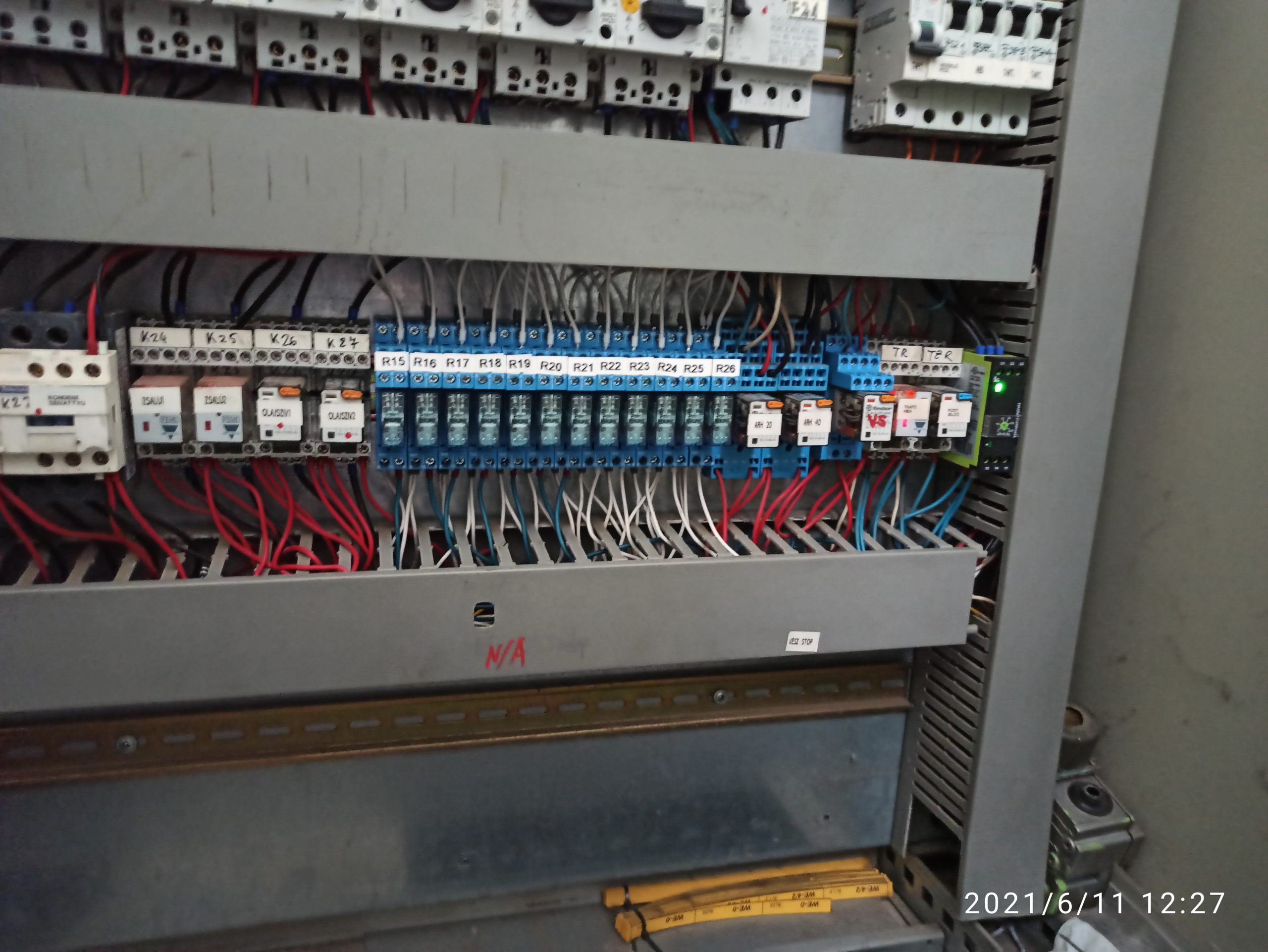

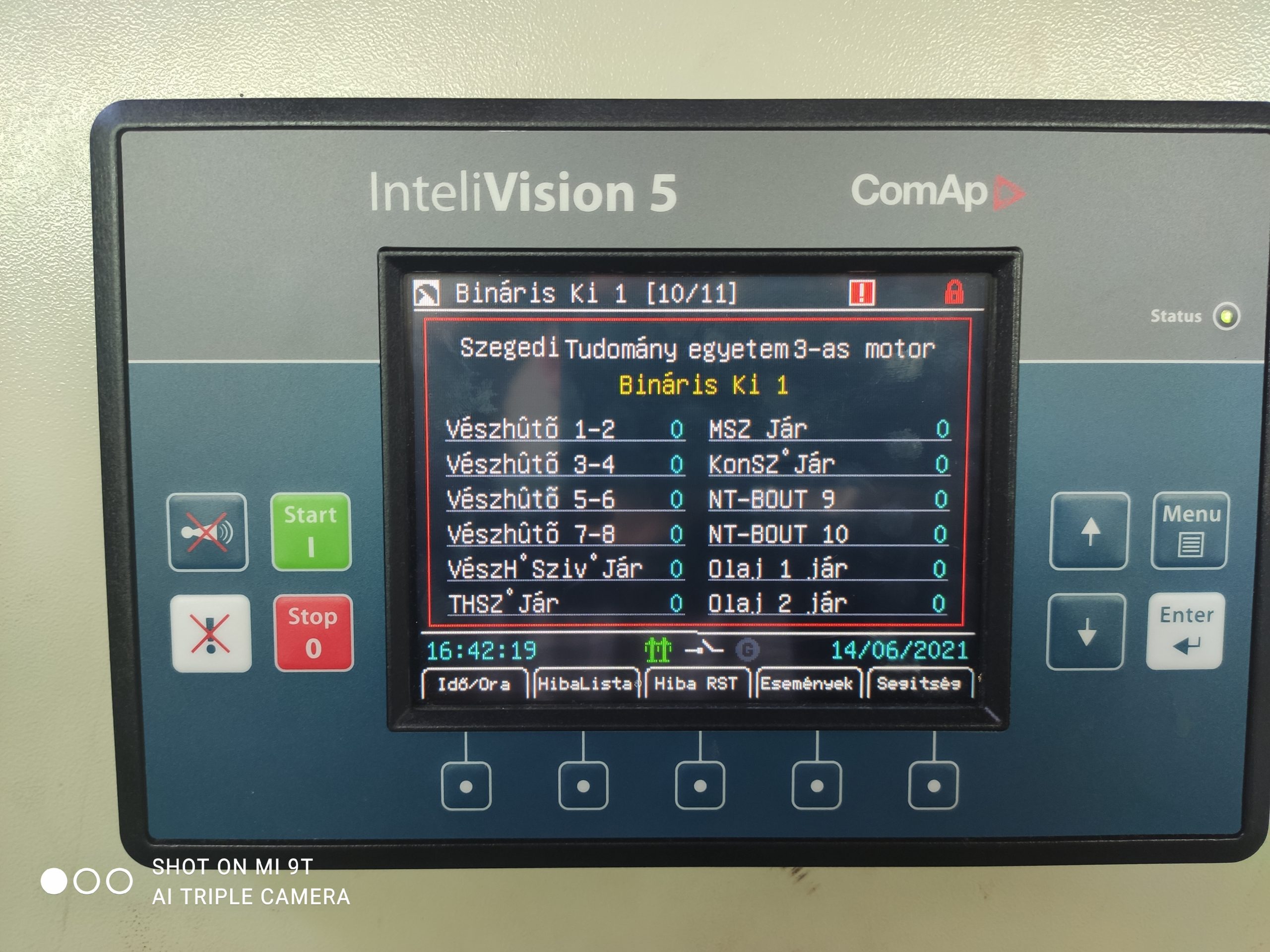

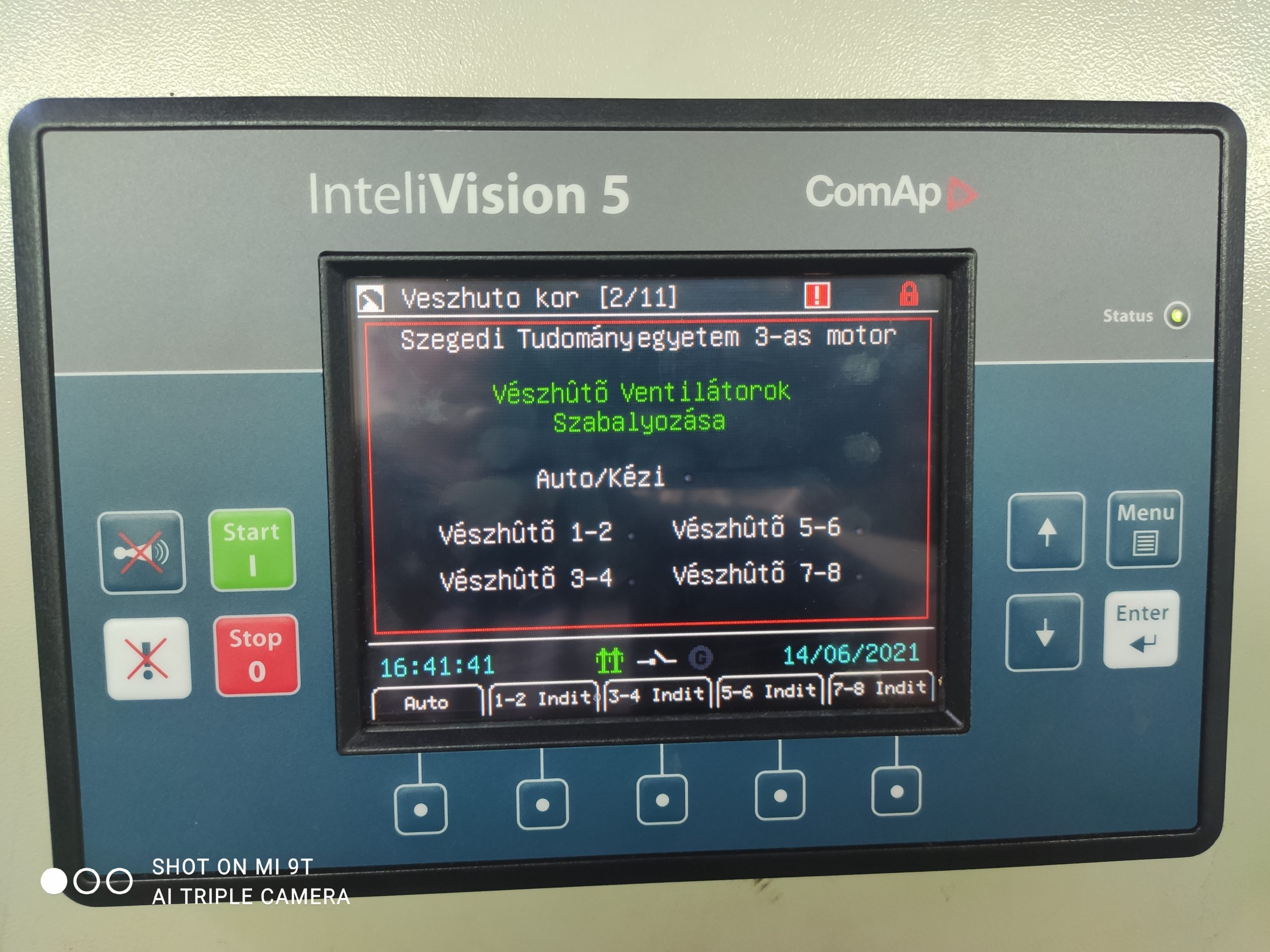

Old automation system

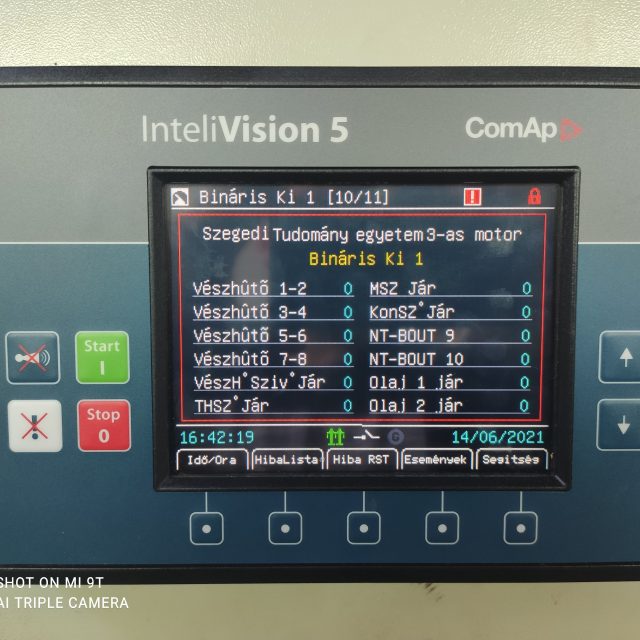

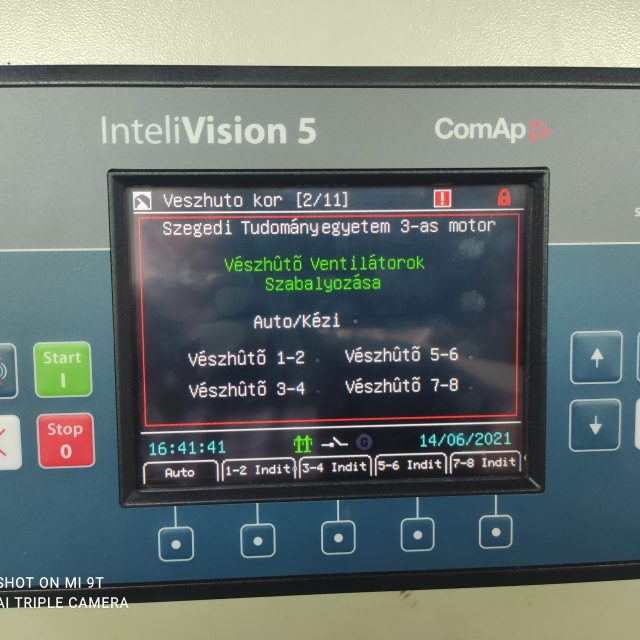

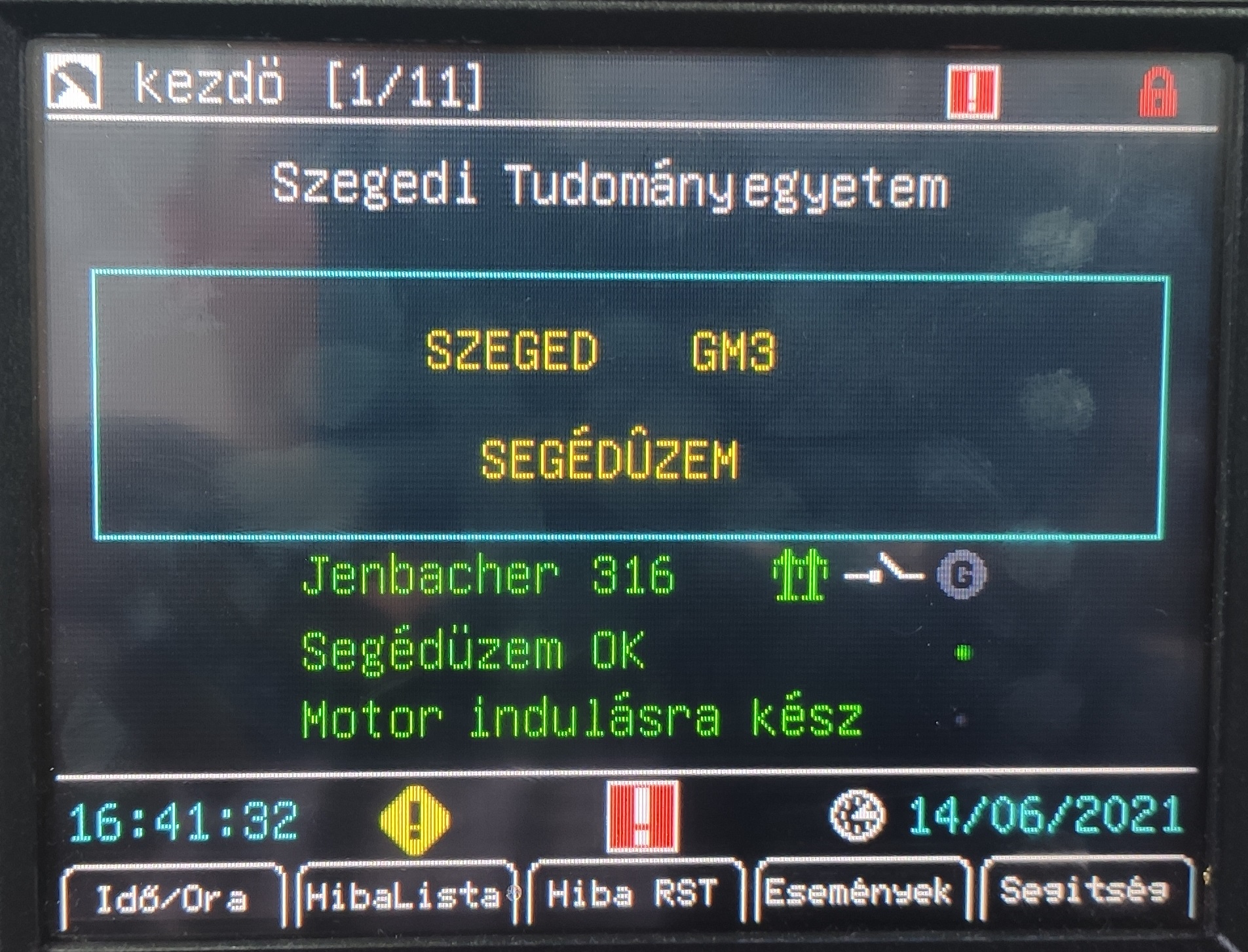

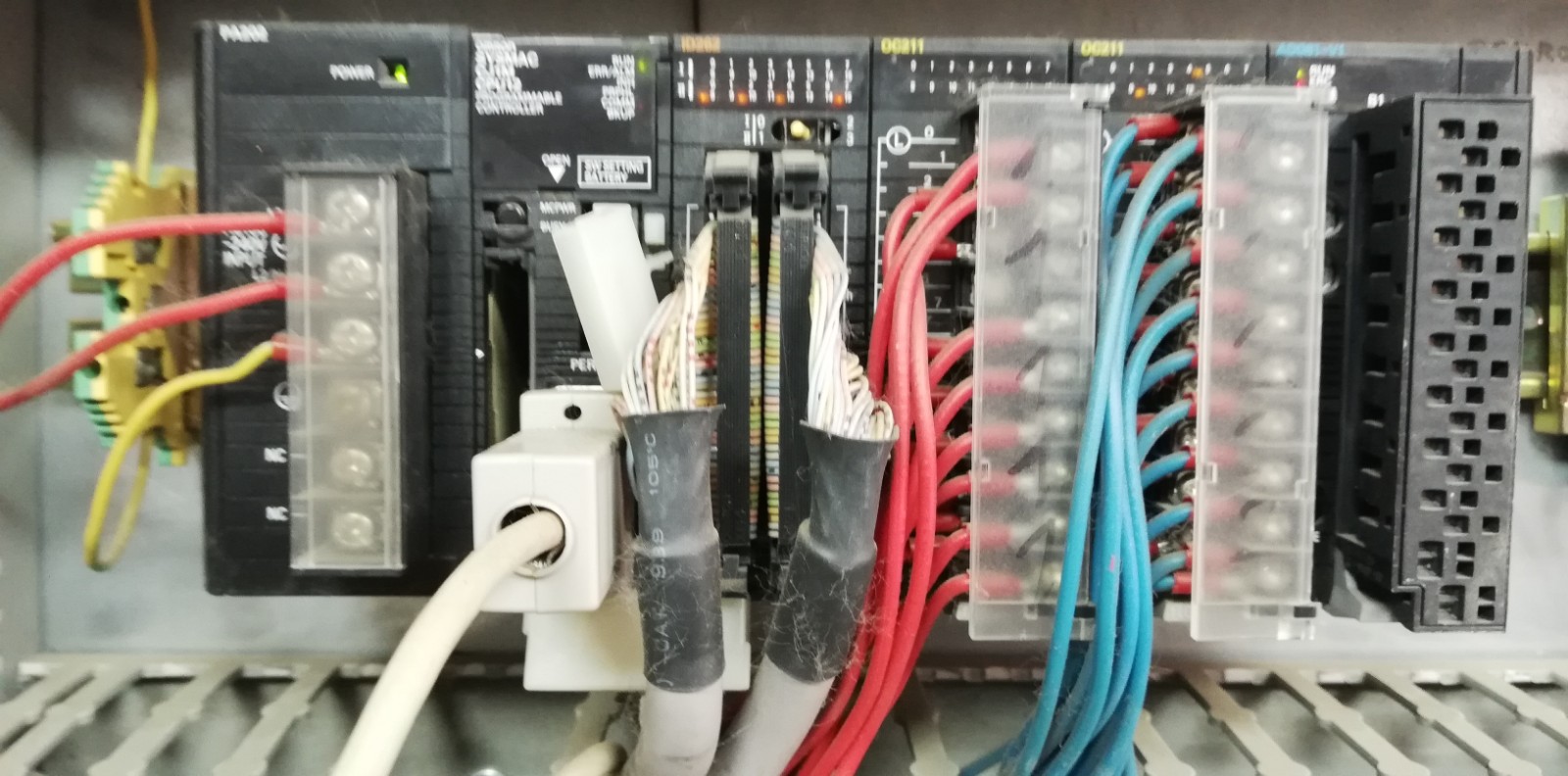

Missing accurate electrical drawings and missing parts from PLC system were not only challenges in this project. Since the first commissioning, couple of modifications were implemented on PLC and automation system. These changes were never reported and all modification traces were missing. With high level of organisation, all the power plant operators and steam boiler experts were interwieved for hystory of changes. Data collection was completed and the project preparation is on the way.

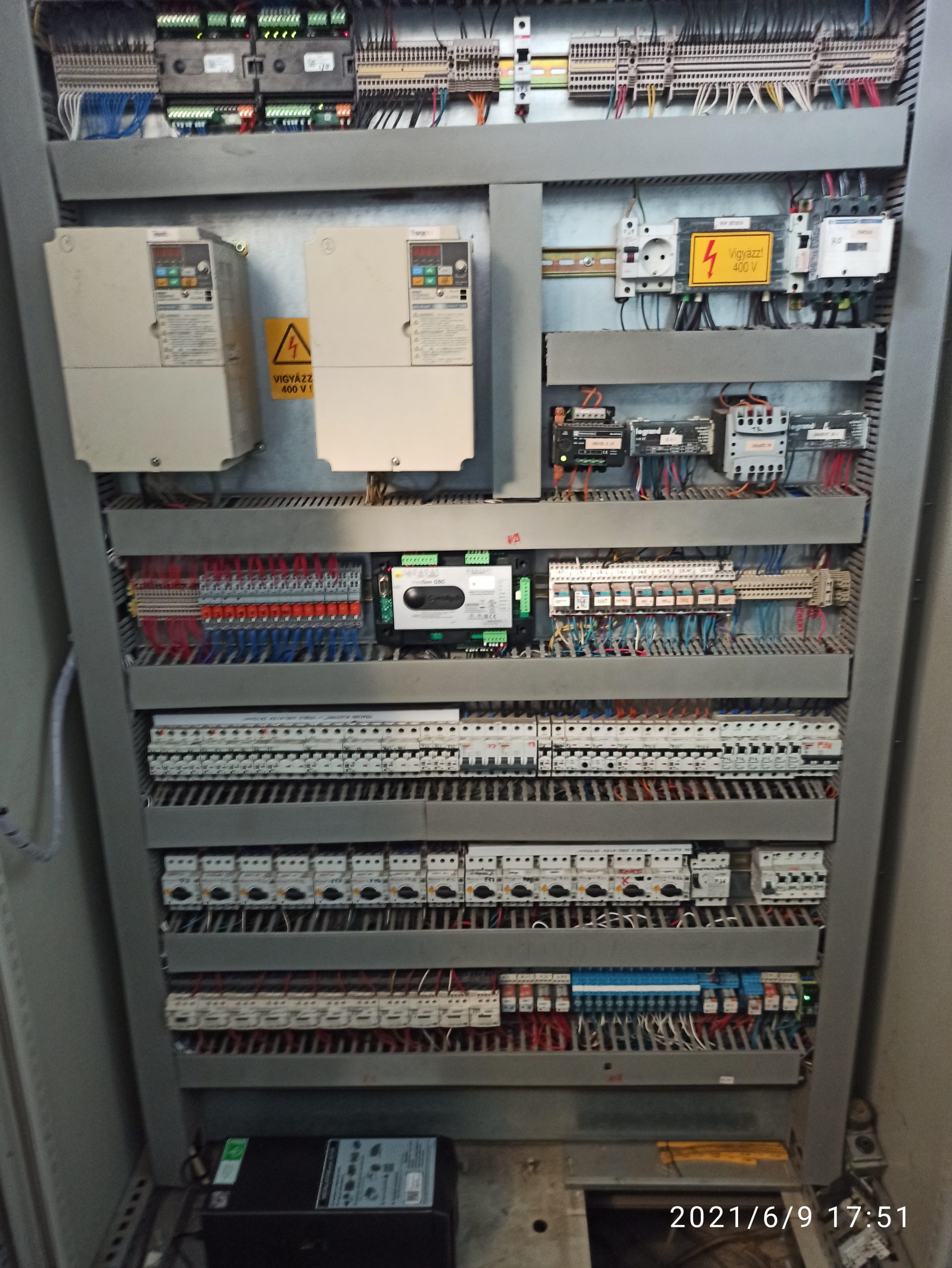

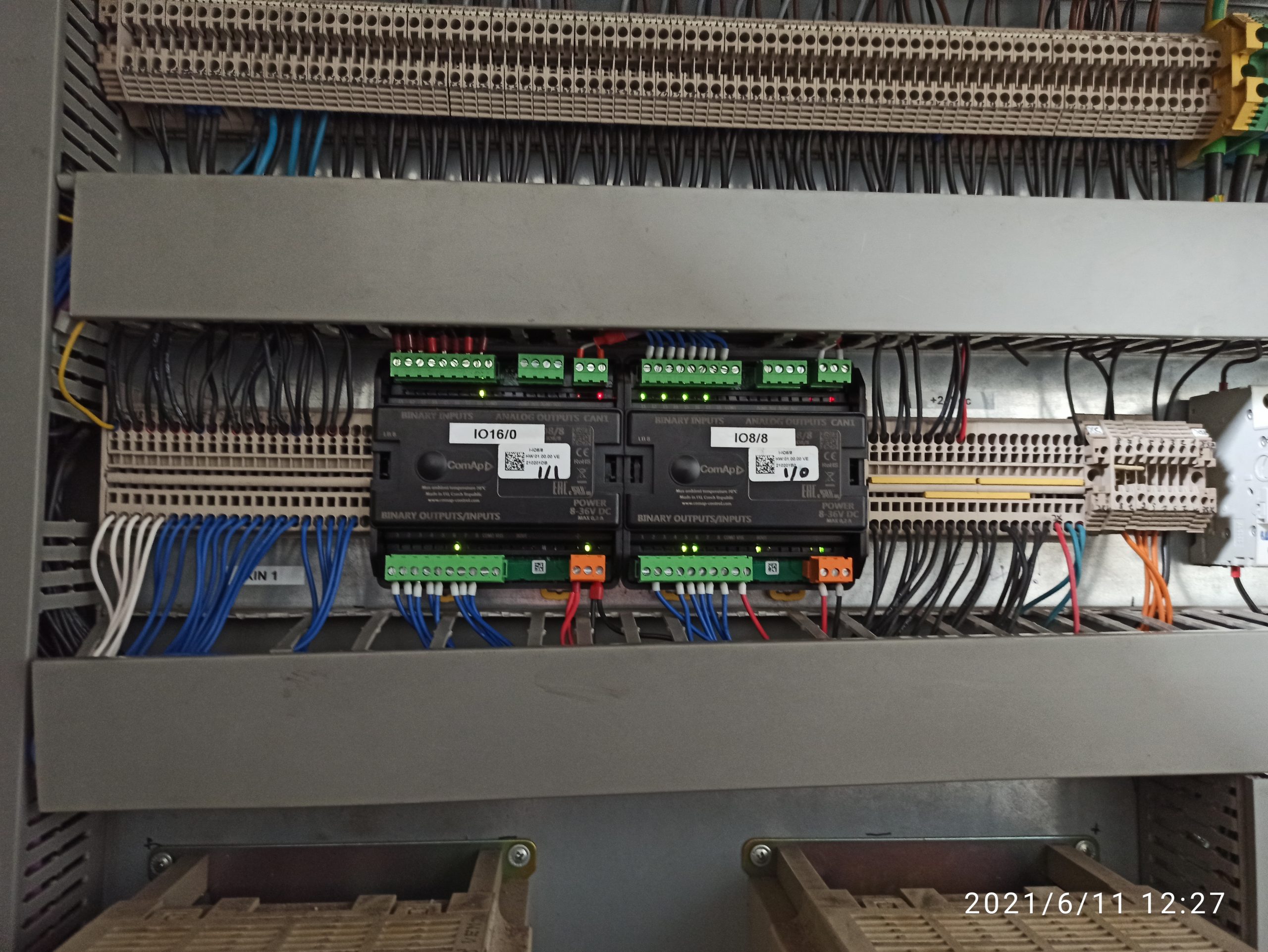

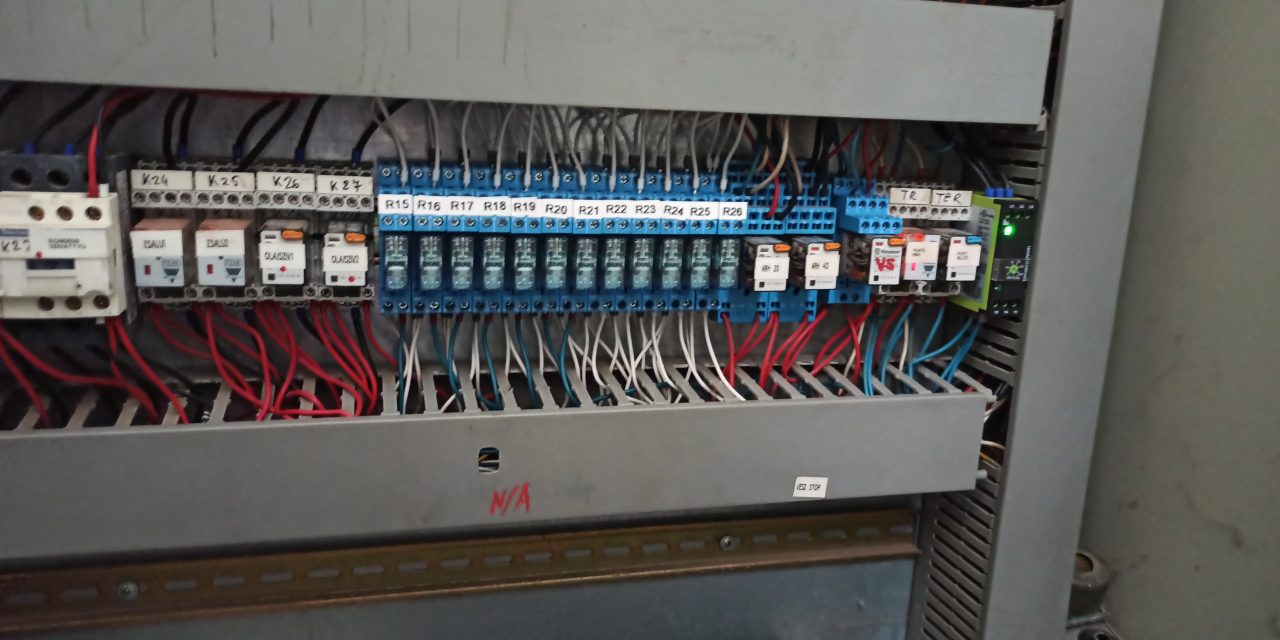

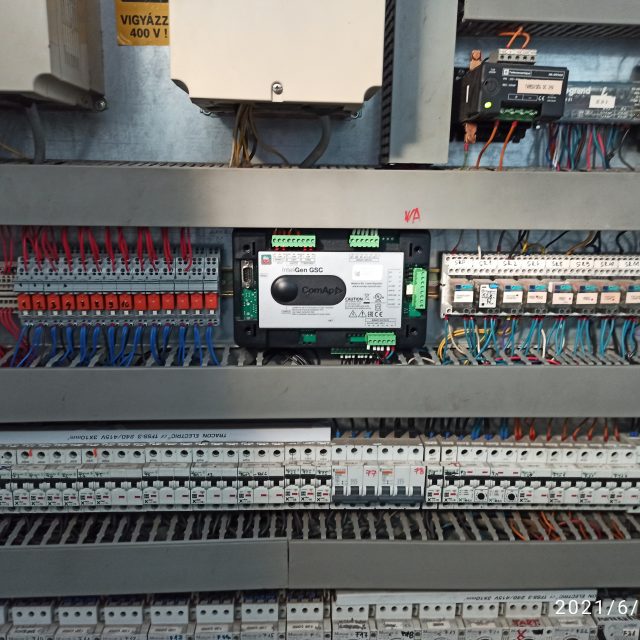

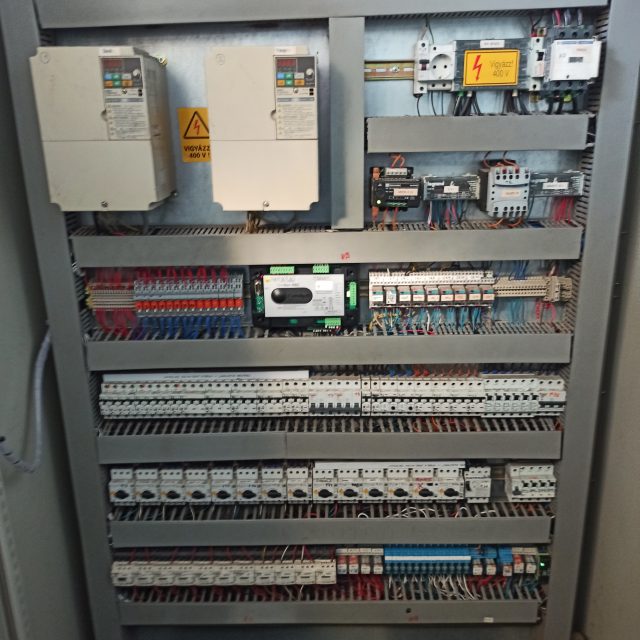

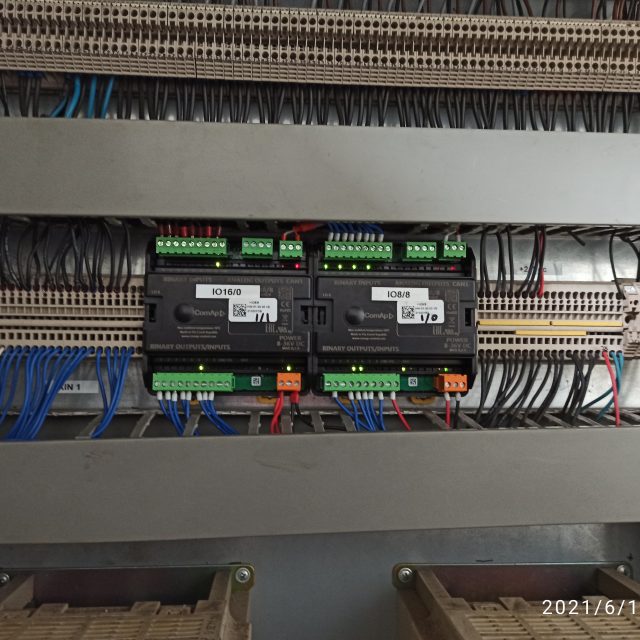

Hardware installation

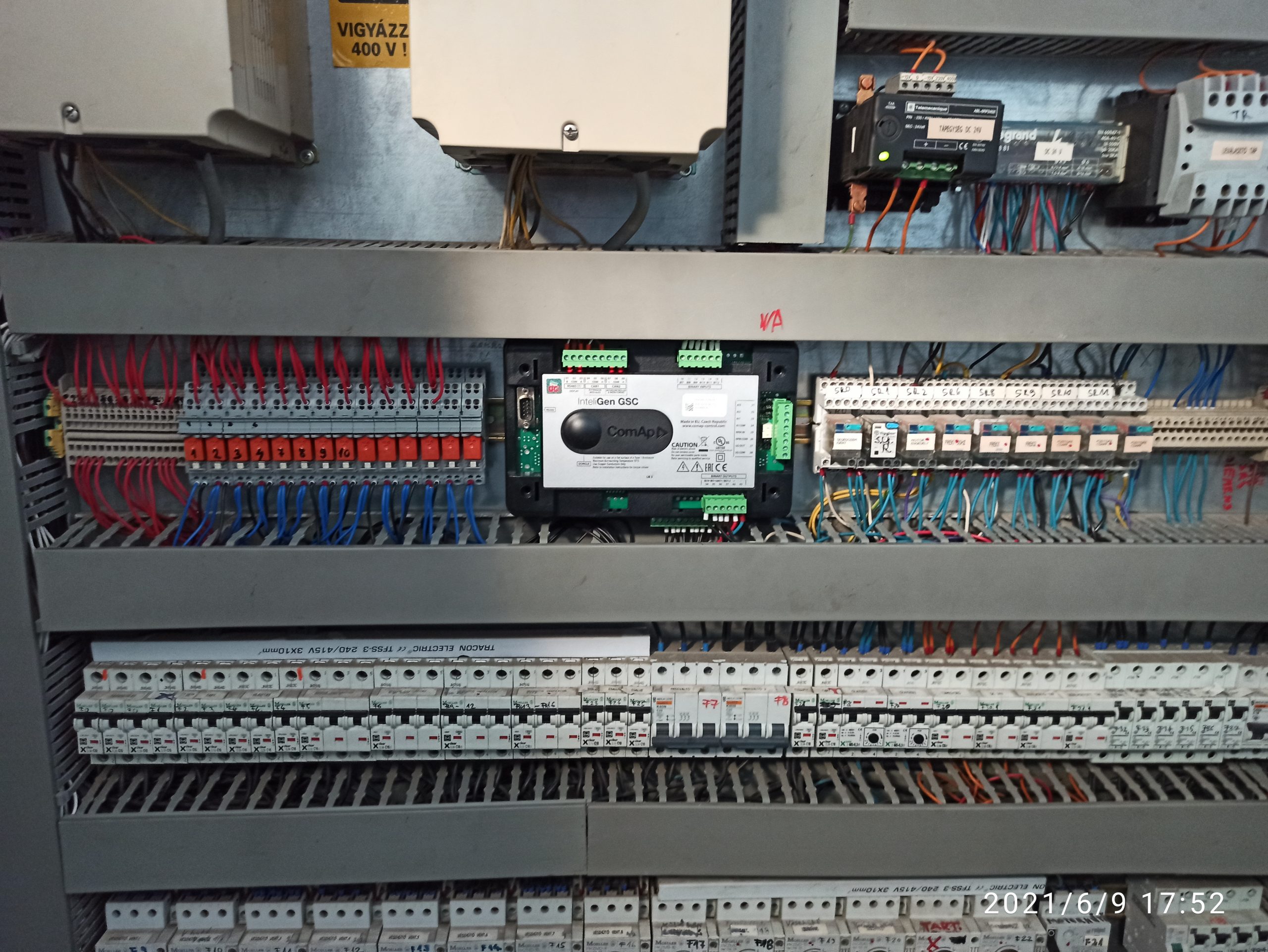

Making a detailed plan with designer team was the key role in this project. Site work was smooth and well executed. The power up and cold tests were done on site where all the inputs were tested and monitoring system was checked for possible mistakes. Output signals were triggered with logical gates. Saftey system was briefly inspected toghether with experts from different areas. Fire fighting system, gas detection system and steam boiler experts have prepared the reports for authority inspection. After all approvals, the hot test period was up comming.

First smoke

“First smoke” expression is widely used in our bussines which means that we are in a final phase of project.

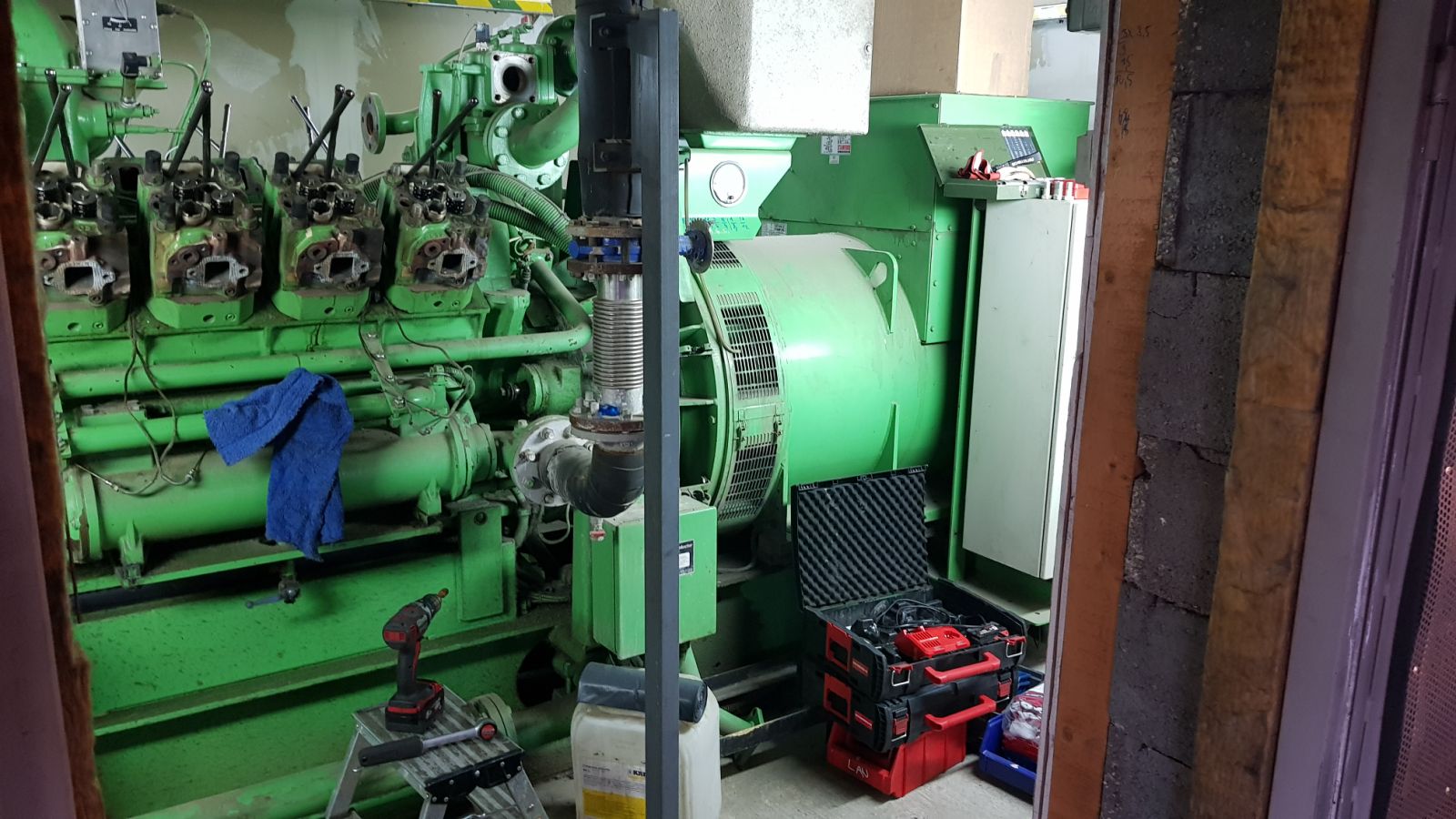

Engine run tests are in progress, so we can inspect the interconnection with the engine automation system. First planned starts and shutdowns were well executed and according to plan. After the first sequence of “Hot tests” we are ready for synchronising test. Let’s connect to the grid.

100% load was achieved without any suprises. Stable engine run can confirm that the mechanical team from PIE has also done the great jobb. After 72h testing period the engine was handed over to customer for further production.

- Location

- Szeged

- Year

- 2020

- Technology

- Advanced

- Service

- Plant automation system upgrade

- Project

- SZTE GM3

- Business type

- Retrofit

- Status

- Completed in 2020