Project Timeline

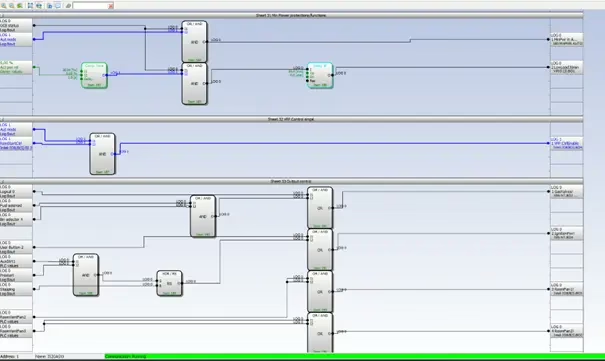

automation. Widely spread older plant control systems are limited in various ways like optimising the

control logic, implementing new features and they are more expensive due to the technology

generation obsolescence.

Flexibility is the future of energy control. New regulations are changing from month to month and

the quick adaption is the root key of business strategy. Now, responding to customer demands in fast

and reliable way can be achieved. With more than 20 years of power plant control experience, PIE

has developed plant management system which is able to completely fulfil customer and TSO

demands.

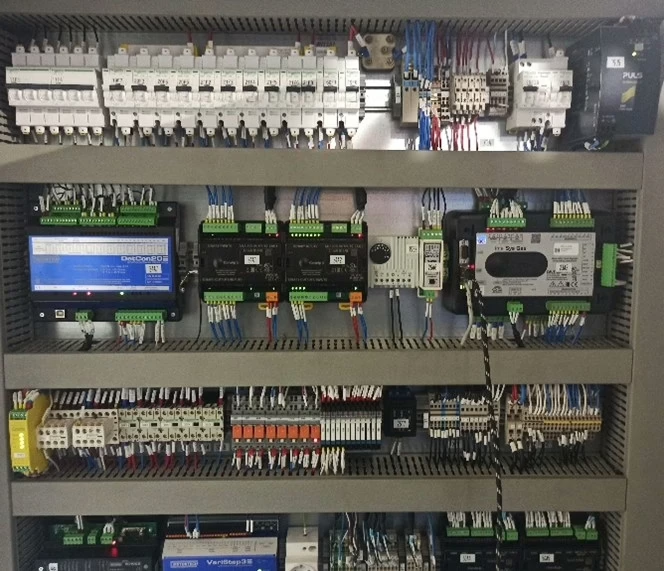

PIE power management system (PIE PMS)

With PIE PMS upgrade the customer will benefit from the site flexibility as to quickly respond to

todays TSO regulation requests, specific process optimisation, SCADA system visualisation with

modern operator’s friendly approach as well as stable and reliable automation system.

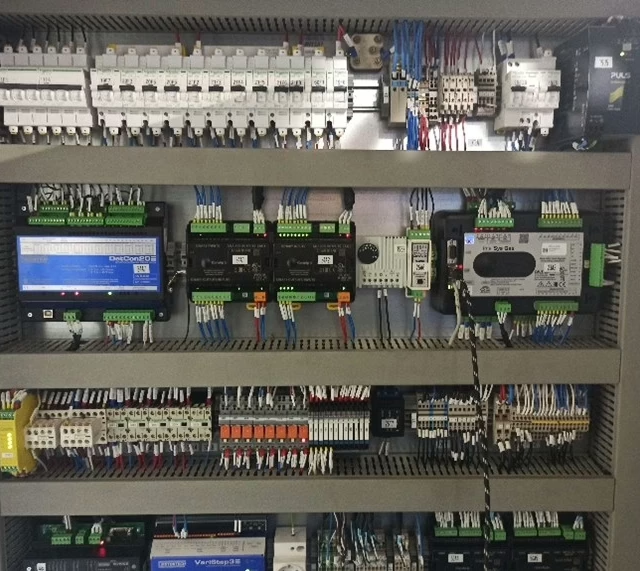

PIE customer orientation approach will optimise the hardware requirements during the designing process.

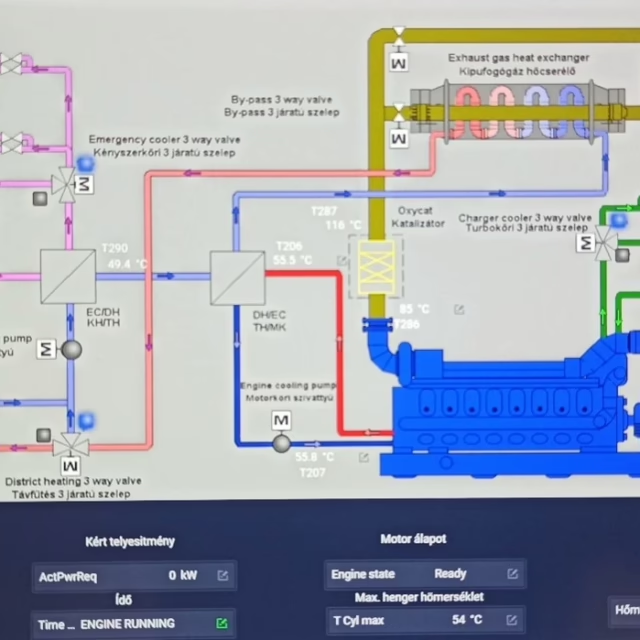

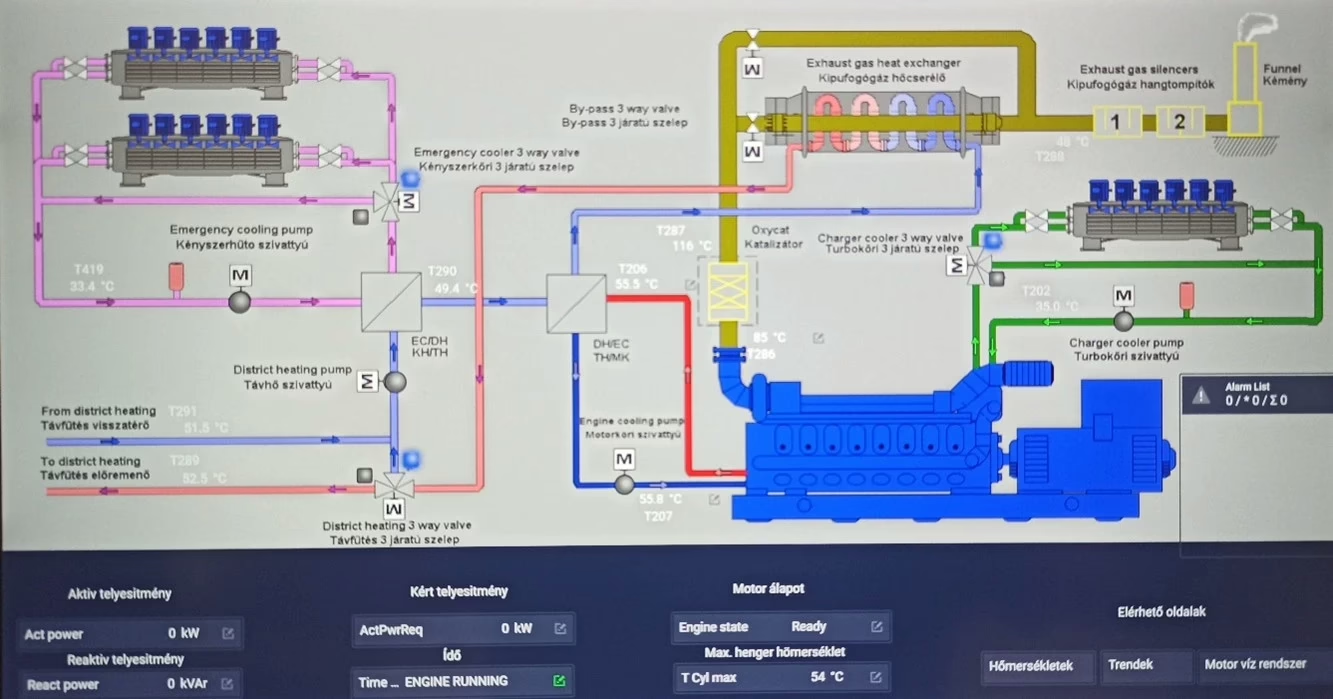

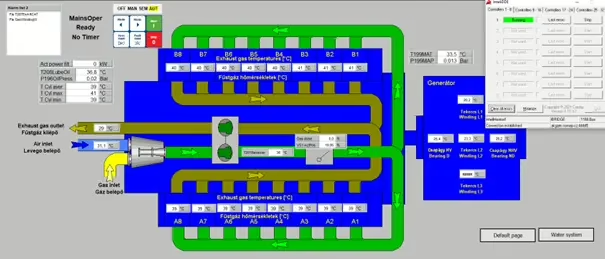

Visualisation of SCADA and HMI-s

Engineering team will visualise the complete power plant processes which will enable operators to

have clearer overview as well as reduced service time.

Remote monitoring for service personnel

Remote monitoring is included in all PIE PMS designs as a standard feature. This feature is reducing

the service time, and it is helping engineers to prepare in advance for troubleshooting.

- Location

- Nyíregyháza

- Year

- 2021

- Technology

- Advanced

- Service

- Plant automation system upgrade

- Project

- Nyíregyháza GM3

- Business type

- Retrofit

- Status

- Completed in 2022